As more industrial facilities adopt geothermal systems for heating and cooling, many are discovering that long-term efficiency depends not only on energy design, but on water behaviour within the system. Biofouling, mineral scaling, and iron bacteria can gradually reduce flow rates, impair heat transfer, and drive up maintenance costs.

At the Swiss chocolate manufacturer Aeschbach Chocolatier, these challenges were threatening to undermine the performance of a groundwater-based geothermal installation — until the company implemented a physical water treatment solution designed specifically to influence mineral behaviour without chemicals. The result: reduced fouling, extended maintenance intervals, stabilised flow rates, and a clearer long-term outlook for geothermal efficiency.

Aeschbach Chocolatier, based in Root in the canton of Luzern, is known for combining Swiss craftsmanship with a forward-looking sustainability strategy. When the company relocated to its modern production facility, it invested in a fossil-free energy concept built around geothermal heating and cooling and supported by a rooftop photovoltaic installation.

This is where AQUA4D steps into the frame.

On a crisp winter morning, CEO of Aeschbach, Jürg Rogenmoser sits in a glass-walled meeting room overlooking the production floor. Behind him, pralines move along conveyor belts while confectioners shape truffles by hand. The scene reflects Swiss precision and control, yet beneath the surface the geothermal system powering the building had been facing persistent operational stress.

“You invest in a renewable energy system to avoid fossil fuels,” Rogenmoser explains, “but when maintenance becomes so intensive, the benefits start to fade.”

Renewable Energy Meets Operational Reality

Sustainability at Aeschbach is not symbolic — it is operational. When the company relocated to its current production site in Root (Luzern), the facility was designed around fossil-free energy. A groundwater-based geothermal system provides heating and cooling, while a rooftop solar PV installation covers nearly half of the company’s electricity needs year-round.

“We produce nearly all of it ourselves,” Rogenmoser explains. “And because our systems run 24/7, the energy we generate is used immediately — almost nothing goes back into the grid.”

The sustainability philosophy extends across the entire value chain, from cocoa sourcing initiatives supporting education and healthcare, to Swiss sugar and milk powder procurement, regional suppliers, and sustainable employee transport. “It only works if you bring the customer along,” he adds. “People need to know that when they buy our chocolate, they are supporting these choices.”

Yet even well-designed renewable systems can encounter hidden technical constraints.

The Hidden Challenge

Shortly after moving into the new building, Aeschbach began experiencing declining performance in its geothermal installation. Flow rates gradually dropped. Heat exchanger efficiency fell. When plate heat exchangers were opened for inspection, technicians discovered what Rogenmoser describes as a “thick reddish sludge” – caused by iron bacteria.

This biofouling restricted water flow and forced the company into an intensive maintenance cycle: dismantling and cleaning the system three to four times per year, along with regular cleaning of extraction and return wells.

“You invest in a renewable energy system to avoid fossil fuels,” Rogenmoser says, “but when maintenance becomes so intensive, the benefits start to fade.”

The problem was not energy generation – it was water behaviour inside the geothermal system. This is where the concept of geothermal water treatment becomes critical.

Technicians at work: prior to AQUA4D installation, regular labor-intensive power cleaning had to take place.

Introducing Physical Water Treatment into a Geothermal System

The turning point came when a technician suggested exploring AQUA4D®. After reviewing case studies and recognising similar sludge patterns, Aeschbach installed an AQUA4D® system in July 2025.

AQUA4D® applies physical water treatment, using resonance fields to temporarily influence the behaviour of solubilised minerals in water — without chemicals, additives, or alteration of chemical composition. Unlike chemical dosing or mechanical filtration, this approach focuses on modifying how minerals interact within pipes, heat exchangers, and wells.

In geothermal applications, where mineral scaling and biological fouling can significantly impact heat transfer efficiency, this type of geothermal water treatment offers particular potential.

Measurable Results Within Months

The operational impact was visible almost immediately. Before installation, cleaning was required every three to four months. After AQUA4D was installed, that threshold was not reached. “By October, I should have already needed the next cleaning, but there was no drop in flow rates,” Rogenmoser reports.

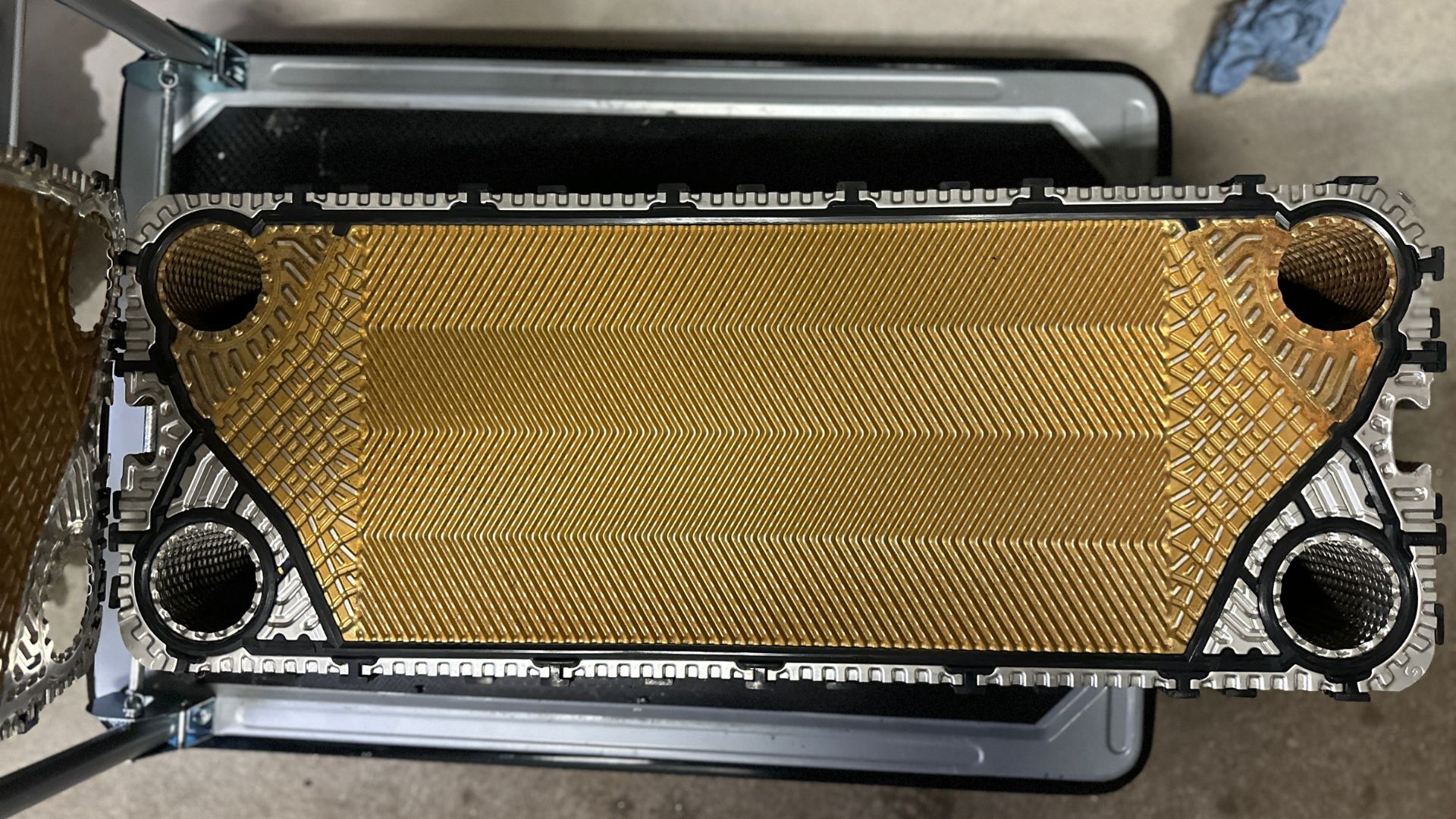

For the first time since installation, the geothermal system operated smoothly for more than half a year. When exchangers were opened for inspection, technicians observed reduced sludge accumulation, lighter colouration of deposits, and, in one exchanger, so little fouling that it could even have remained closed.

“That was unheard of,” says Rogenmoser. Maintenance contractors, previously tasked with labor-intensive power-cleaning, noted the difference immediately. The improvement was not cosmetic – it directly affected system availability, performance stability, and water pressure.

“Astonishing” results – almost-clean heat exchangers after 6 months.

The Financial Case for Geothermal Water Treatment

The economic implications are substantial. Frequent cleaning of heat exchangers and wells carries direct labour costs, contractor fees, and downtime risks. More importantly, when geothermal efficiency declines, supplemental electricity must compensate for heating and cooling demand.

Aeschbach estimates that if the number of required cleanings is merely reduced by half, the investment will pay for itself in under two years. If current performance continues, amortisation could occur within a single year.

“I’m optimistic,” says Rogenmoser. “If this continues, AQUA4D will make our geothermal system viable for many years to come.” This highlights a broader opportunity: geothermal water treatment is not only a sustainability measure, it is an efficiency and cost-control strategy.

Technicians and engineers involved in the system, as well as casual observers, are watching closely: “Everyone involved is eager to see how this develops,” Rogenmoser notes. “There are many systems out there with the same problem. AQUA4D could help a lot of companies. I used to think we were the only ones with this issue, but I’ve learned it’s widespread. What we’ve seen so far is positive, and the technology fits perfectly with our philosophy. It’s simple, ecological, and low-maintenance. I can fully recommend it with a good conscience.”

When Water Becomes an Operational Lever

Ultimately, renewable energy systems are only as effective as the water that circulates within them.

At Aeschbach Chocolatier, physical water treatment has transformed water from a hidden constraint into an efficiency lever. The case demonstrates the growing industrial relevance of geothermal water treatment – not as a theoretical sustainability concept, but as a practical method for improving system reliability, reducing maintenance, and protecting long-term energy investments.

Swiss craftsmanship, renewable energy, and advanced water technology now operate in alignment. And AQUA4D®, quietly integrated into the system, has become part of the recipe.

Switzerland

Geothermal Water Treatment

Success Story

“AQUA4D could help a lot of companies; there are many geothermal systems out there with the same problem. What we’ve seen so far is positive, and the technology fits perfectly with our philosophy. It’s simple, ecological, and low-maintenance. I can fully recommend it with a good conscience.”

– Jürg Rogenmoser, CEO, Aeschbach Chocolatier

⬆️ Watch as Jürg Rogenmoser, CEO of Aeschbach, explains the problem and how the solution unfolded.

AQUA4D’s Markus Schwery conducts his inspection, 6 months after installation.