This interview originally appeared in Planer + Installateur magazine. See the original in-depth German version here.

The company co-founded by Walter Thut, AQUA4D, pursues its own unique approach to physical water treatment in the water sector. In this interview, Walter explains the advantages of his technology and the potential applications in the buildings sector.

Walter Thut, your company has been around since 2004, and from the very beginning you pursued quite independent paths in water purification/quality and the fight against limescale and corrosion. Tell us about your beginnings.

When I founded the company with Dr. Eric Valette, who succeeded me as CEO, in 2004, we were excited as researchers and engineers about the possibilities of physical water treatment. We carried out projects in wastewater treatment plants, thereby improving the settling behavior of suspended solids, which allowed us to optimize the biological stage and thus promote the conversion of pollutants. We were able to rid lakes of microalgae and were all over the media because of such projects, especially in French-speaking Switzerland.

On the other hand, we still had little idea of a strategic business plan and marketing and therefore got bogged down in far too many application areas. The experience with the professionals in the application area of buildings and sanitary installations was also hard and difficult at first, as they were very skeptical about new technologies.

Early days: the AQUA4D team in the 2000s

You focus on physical water treatment and have done pioneering work here. How did you come up with this?

In my early years as an engineer, I specialized in concrete. After many years in various functions in concrete production, I worked in the early 1990s for the company MBT. I was responsible for product management of concrete admixtures. We found that even with the best high-tech chemical products, we were occasionally faced with problems that we couldn’t explain.

It was only when I started to look at water more closely that we found old research work from Russia that could improve the concrete quality through physical water treatment. We also ran tests and applications with the physical treatment systems available on the market at that time and were able to observe a significantly improved concrete quality. The crystallization processes changed, and the density of the concrete was visibly better. There was no doubt that the physical water treatments could achieve a significant effect.

What advantages does your technology have compared to other, similar processes?

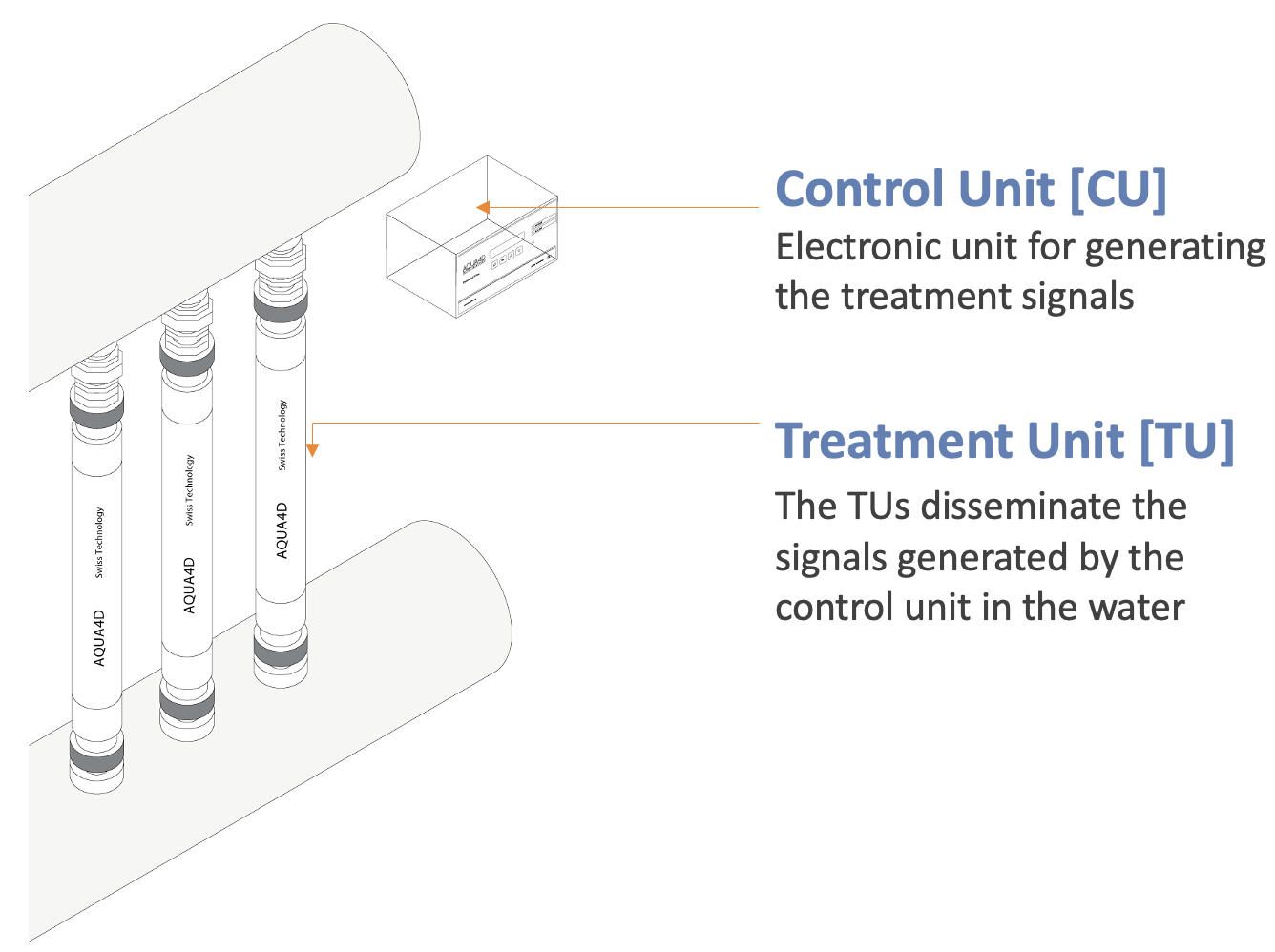

When you treat water physically, the effectiveness generally decreases over time. This is also true for most chemical processes. In contrast to other physical processes, we have concentrated on developing an overall concept with which the effect lasts over a long period and over large distances. In other words, we ensure that our resonance fields propagate throughout the entire pipeline network 24/7. Whether the water stagnates in the pipes during a two-week vacation, for example, or is at a standstill in the school building for a long period, is irrelevant for our systems. As soon as the tap is opened again after the vacations or at the start of school, treated water flows immediately. Our technicians also search for and eliminate possible magnetic, electrical and/or electromagnetic interference fields that could have a very negative effect on the water. In terms of frequencies and their use, I think we are a significant step ahead of the entire industry.

To what extent are your successes in water treatment covered scientifically?

When you introduce a new technology in a traditional, strongly “hardware”-oriented industry such as construction, the standards understandably always lag behind somewhat. Regional universities are also unable to adopt these new technologies quickly enough. Moreover, in such cases, there are no suitable standard test procedures that can take into account and assess such a technological development. Standard tests, designed primarily for softeners, are not suitable for our special physical treatment systems. Since there are no official test centers for a technology like ours, it was all the more important for us to demonstrate the real success in buildings beyond doubt.

For more than ten years, we have been able to provide transparent proof that corresponds to reality by consistently installing “monitoring tubes”. Among other things, this distinguishes us from our competitors. Scientific studies have clearly demonstrated the systematic change in water properties after treatment by AQUA4D®: The University of Nantes in France, for example, demonstrated early on the change in the zeta potential of water, which is central to the behavior and interaction of electrically charged particles in connection with constituents in water (for example, ions).

You mentioned at the beginning that we are also taking a different approach to drinking water hygiene.

We have been awarded significant amounts from the Eurostar Fund for Research and Development. With these funds, university research has, among other things, scientifically proven the influence of our technology on biofilm and the resulting effect on bacterial development on several occasions. The effect on calcium carbonate crystals (limescale), which prevents the build-up of deposits and breaks down existing ones, has also been confirmed. These results were also published, among others, in the renowned “International Water Research Magazine”.

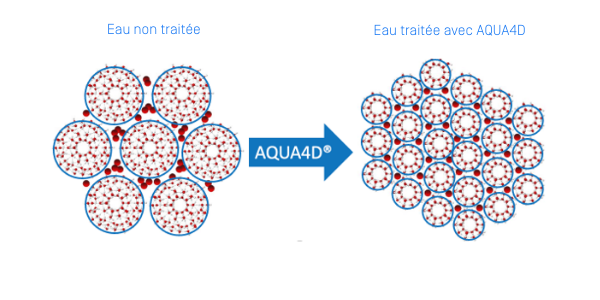

A graphic illustration of the technology’s effect on water clusters.

Periodic Photo of the monitoring tube.

Sustainability and environmental friendliness are at the forefront of your solutions. What are and were your principles in this regard?

Of the many possible areas of application, we deliberately chose hygiene for drinking water and food production. This is primarily because we are dealing here with what are probably the most important goods for all life on earth. This is a decision that goes hand in hand with sustainability. Reducing the use of chemicals in these areas of application was a priority for us. As water specialists, we are also aware of the situation surrounding the current and future availability of water, the most important resource for food production. The most important principle is to optimize the use of water and achieve savings wherever possible.

Today, in many regions of the world, we are concerned with saving as much water as possible. If we, as a human race, fail to do this, we will soon have food shortages. Wherever we can replace ion exchangers, this will immediately save around 10% pure drinking water and also relieve the burden on wastewater. Wherever we can replace reverse osmosis processes in agriculture where the water is too saline, we save much more water and also around 90% energy. Our principle here is that our solution should also be technically and economically better.

What disruptive factors do you eliminate with your technology?

First of all, it’s about healthy water and clean pipes. In drinking water, chemical additives, including technologically produced salts, are clearly a disruptive factor that we want to eliminate. In pipes, deposits of limescale, corrosion or biofilm are disturbing factors. Of the three, biofilm is probably the most interesting, because biofilm is the ideal habitat for the development of bacterial cultures. It can also lead to pathogenic agents, and this can result in health risks that are often not noticed for a long time.

When you take a water sample and analyze it for bacteria, you are measuring the actual bacteria present in the water. However, one probably does not know about large bacterial herds that are suddenly washed away by the water flow. In addition, bacteria multiply in biofilms and are very difficult to eliminate. We reduce this risk to almost zero by removing the biofilm from the inside of the pipe. If I mentioned electrical, magnetic and electromagnetic fields as disturbing factors for the water before, we do not eliminate these. But we have developed an overall concept that massively reduces the impact on water quality.

What are the possible applications of your treatment devices in the building sector?

Today they are used mainly in older buildings and in new buildings in both cold and hot water. These are residential buildings, but also industrial buildings or hotels, old people’s homes and nursing homes and, increasingly, public buildings belonging to municipalities, cantons or the federal government. We also have a strong position in larger buildings, partly because we can maintain efficiency over several kilometers of pipe network.

It is difficult to break down existing limescale, rust layers, or biofilm with conventional water treatments. What is different with your cleantech?

Our concept is not to add something to the water – we act directly on the water molecules themselves, having a clear effect on the properties of the water. Thus, our treatment can not only better dissolve minerals, but also better hold gases in solution. It is often wrongly claimed that water cannot break down limescale, which of course is not true. How else can calcium and magnesium get into the water? By breaking down entire mountains of limestone over the course of time.

Thus, a few millimeters of limescale in pipes, at least theoretically, should not be a problem. We break down rust together with limescale; it is always only a part of the whole deposit. To come back to water hygiene: the vast majority of pipes are dirty inside and full of deposits within a few years. With AQUA4D®, we can remove these deposits or prevent them from forming in the first place.

You emphasize that microbiological analyses are more concerned with the water and not the biofilm – hence your focus on the biofilm: How does AQUA4D® do this and what is the effect on bacteria?

Our water treatment changes the sums of the electrical charges at the interfaces between water and other materials. Certain substances are attracted, while organic material – which makes up the remaining 5% of biofilm – is repelled. As a result, no new biofilm can settle and existing deposits are detached. In contrast to the decomposition of limescale, this happens very quickly after commissioning.

They say electrical installations and water quality are connected. What does that mean for the installers in our industry?

Each water molecule is a dipole, which is is on the one hand an antenna and on the other hand reacts to any electrical and magnetic fields. The most common problems we encounter are grounding problems and vagrant currents on water lines. We have to detect these during the installation of an AQUA4D® unit and then eliminate them as these fields can interfere with our signals (resonance fields). For the installers this means that they must receive from our technical support precise instructions about what must be taken into account during installation. Adhering to these instructions is essential for the optimum efficiency of our of our systems. However, it would be much more helpful and sensible for a generally better quality of living and water, if installation standards for sanitary and electrical engineering were brought into line. The frequencies and fields of electrical installations are not usually compatible with those of water, and the more they affect it, the more the quality of the water and its their physical properties are impaired.

What are your next projects in our industry? What will you implement with AQUA4D®?

In the field of energy and heating, we have developed an ideal solution for for minimizing costly maintenance in geothermal energy. It has already been successfully implemented in practice and has promising future prospects. We will soon present this solution to a wider audience in detail. We also want to help the sustainable transformation in the buildings and industrial sectors. Today, there is a lot of talk about energy savings and CO2 reduction. However, the construction industry must place much more emphasis on water savings and high sanitary sustainability standards. In the future, it must not be the case that walls have to be broken down due to renovations of water pipes, affecting users or residents in the process. This is the stone age and no longer meets Swiss quality standards! ■

Find out more about Sustainable Buildings with AQUA4D®:

Switzerland

Water-Smart

Sustainable Buildings

Eric Valette (CEO) on the early development of the company and technology.