Thanks to the ongoing energy crisis, there is a growing focus on the potential of alternative heat sources, notably geothermal heat pumps. However, water and soil factors in an at least 30% of Swiss regions create conditions which threaten the efficiency of such installations, leading to costly maintenance and operation interruptions.

No sustainable solution has yet existed. Now Valais-based AQUA4D have shown their water treatment innovation can finally solve these niggling issues with the geothermal rollout, and help speed up the green transition of the country’s energy supply.

Biofilm and iron bacteria: a tiny menace causing huge issues

Contrary to the closed circuits of heating systems, near surface heat pumps are constantly bringing in new water – and hence new bacteria and minerals – from groundwater, which is extracted and put into a heat exchanger. This can cause a buildup which can take the whole system out of action.

Most importantly, in areas where iron or manganese are present in the soil, this will be introduced when groundwater is extracted. When oxidized, this attracts certain bacteria – creating problematic biofilm and slurry which often get exponentially worse. Up to now, this has needed costly maintenance requiring labor hours and operation interruptions.

What’s more, as the water is sent back underground, bacterial deposits and slurry will start clogging the soil, making it difficult to bring the water back into the ground. To avoid groundwater pollution the use of chemicals is forbidden, so the industry has been desperate for a sustainable solution – and one finally exists.

Treating the water to protect the system

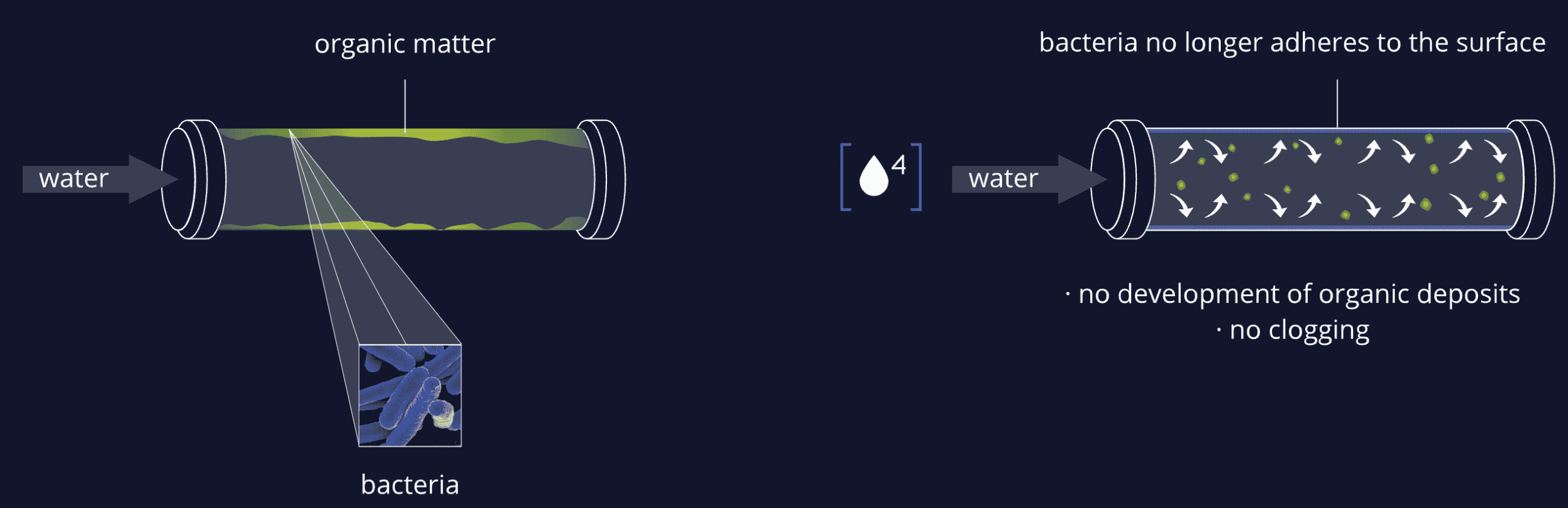

AQUA4D® simultaneously protects the whole system (pump, piping, heat exchanger) from limescale, deposits and iron bacteria. Installed between pump and heat exchanger (see diagram to the right), the effects on the treated water are maintained throughout the system and back into the ground.

What are these effects? Thanks to the technology’s modification of water structure, bacteria and deposits no longer build up and do not stick to piping or systems. With ongoing treatment – itself requiring very little power consumption – the whole system is maintained clear indefinitely. Without such treatment, buildup can cause blockages within a matter of weeks.

For several customers throughout Switzerland, this has meant uninterrupted operation for a matter of years – saving not only maintenance troubles but energy and costs in the process.

Case study: FANUC (industry)

Several times a year, a crew from Pärli AG used to go out to clean the heat exchangers at FANUC, where the groundwater heat pump showed insufficient flow and malfunction reports. “We had to de-assemble the plate exchangers and clean them with high pressure water,” reports Pärli team leader Pascal Schatt. “Each time, they were completely clogged up with iron bacteria.” The team tried chemical cleaning, high pressure water and mechanical cleaning – to no great success.

After consulting AQUA4D® technicians, two 360G-B Treatment Units were installed in FANUC’s groundwater supply line and put into operation. “The result was absolutely amazing,” reports Schatt. “We were simply not called upon again!” After operating for about a year and a half without any problems, the plates and filter were removed for inspection. “Our amazement grew once again: everything was cleaner than when it was installed, even shining!”

This is how, after years of issues and regular intensive cleaning, FANUC discovered that AQUA4D® was the most effective of all – leaving their plate heat exchangers as good as new and solving long-standing iron bacteria issues. The images compare chemical treatment, high pressure water and mechanical cleaning (left), with a heat exchanger after 11 months of AQUA4D®.

FANUC now run operations 365 days a year and have had no more issues, saving time and money.

Lastly, persistent infiltration problems were resolved. These were previously caused at the point of re-injection of the water into the ground, because the water was full of iron bacteria, Today, instead of being a mess with leachate gravel and biofilm, it has become a flourishing garden.

Case study: Brigerbad (apartments)

This new residential building in Valais was equipped with a geothermal installation for heating in winter and cooling in summertime, planned for year-round operation. Shortly after installation, the system was blocked by iron bacteria, resulting in temporary replacement by an energy-intensive electric boiler. At the end of 2021, the Canton of Valais approached AQUA4D to enquire about trialing this technology, which was then installed in January 2022.

The project was closely followed, with data showing no more fluctuations and a constant 47 degrees over 3 months – showing AQUA4D is helping maintain a stable temperature between incoming and outgoing water.

Case study: Lenk (municipal)

As a municipal sports facility, Kurs und Sport Zentrum (KUSPO) in Lenk is in continual use and needs to maintain year-round constant temperatures. Unfortunately, they had to get used to their heating systems being cleaned every 4-6 weeks – causing not only disruptions but a not insignificant 4000 CHF of costs each time. Until AQUA4D® arrived, of course.

The consulting engineer from WELATEC explains: “We can see that the situation has improved massively and there are no longer any problems. Since installation, the heat exchanger has never had to be cleaned again. Thus, the renovation with AQUA4D can be described as a complete success.”

AQUA4D: expediting the geothermal rollout

Hard water coupled with unfavorable mineral conditions was until now preventing the possibility to rely on near surface geothermal energy in up to a third of the country. In these settings, geothermal heat exchangers could otherwise not be used without prohibitive and expensive maintenance considerations.

With water successfully treated at various kinds of geothermal installations, AQUA4D® helps pave the way to more widespread adoption of sustainable heat pumps. And with spiraling energy costs threatening an uncomfortable winter, there has never been a better time to do so.

Switzerland

Geothermal

Sustainable Buildings

“Before, we had to remove and clean the heat exchanger every two to three months. Since then, for more than four years, we have never had to clean it.”

– Omar Durmaz, FANUC Switzerland GmbH