The Paulman family has been operating and harvesting in Southwest Nebraska since 1985, with crops including popcorn, oats and soy across 6500 acres. They pride themselves on responsible resource use, but like others across the USA these resources are under strain. Now a combination of regenerative approaches and innovative technology is future-fitting their production.

Nebraskans are used to water shortage, having lived through drought crises in the 1890s, 1930s, 1950s and more. Farmers here are also accustomed to doing more with less – the NRDs here were among the first in the country to set annual water allocations back in the 70s. Now with reduced rainfall and declining aquifers such caps have steadily increased, adding further pressure to farmers. “This has become a major issue, so we have to figure out how to do a better job with the water we are allocated,” says Zach Paulman, the third generation farming here in Lincoln County.

Nevertheless, such restrictions have not dampened the enthusiasm for growing. If anything, it has fostered greater innovation and a sense of water stewardship not seen in other places. In the case of Paulman Farms, this led them to a regenerative approach – long before the recent buzz around ‘reg ag’.

The Paulman approach

For Zach, it’s about pride as much as anything else – for themselves, for their land, and for their operations: “We had to find a way to get more efficient which in turn made us more profitable,” he says. “It’s also about pride and trying to be a better steward of the land while bettering ourselves – the status quo is not where I want to live.”

And their regenerative methods are far from the status quo. This encompasses everything from cover crops to no-till, from responsible water management to minimal fertilizers. As just one example, in 2022 they used around 0.6 lb of Nitrogen per bushel of corn, compared with the standard of 1.0 lb. “We hang our hats on having a regenerative farm here – we try limit water, nitrogen use: we try be as efficient as humanly possible,” adds Zach.

It is also about going against agriculture’s historically single-minded focus on productivity. Regenerative ag lays more focus on the long-term productivity of the land, but also maintaining productivity while using fewer resources – principles Zach’s father, Roric Paulman, has been championing for decades:

“It’s proven now that in agriculture we’ve done a good job but we’re degrading our soils over time. The whole conversation is around yield but it should be more about the benefits that come with treating the soil biology appropriately, and working that backwards to an economic return as opposed to maximizing all the time,” says Roric Paulman. “With these approaches, we’ve had remarkable results several years in a row. Regenerative, sustainable, call it what you like but I like ‘the assignment of continuous improvement’.”

It was with this spirit of continuous improvement in mind that Paulman Farms became the first in the USA to use the brand-new AQUA4D® Max system for pivot irrigation.

AQUA4D® for soil regeneration and water penetration

It’s simple math: if Paulman are to maintain production in the face of increasing pumping caps, they will need to increasingly get by with less water. With Nebraska’s 100-degree summers and more frequent droughts, this would be a challenge without making changes. “Trying to grow a 250-bushel corn crop or 7000 lb popcorn crop on 13 inches of water gets very difficult,” says Zach matter-of-factly. “That’s where the AQUA4D unit comes in.”

With this technology’s track record for saving water in various crops around the world (including notably almonds and pistachios in California), similar effects were optimistically expected for its new H-A Max system for large crops. After R&D funded by the EU’s Horizon 2020 program, the new system is designed to treat the large flow-rates required for center pivot systems like those used by Paulman. By treating the water as it passes through, water penetration is increased in the soil and minerals are better dissolved. Would the AQUA4D® system pass the tough conditions encountered in Southwest Nebraska?

Impressive Results

To get a true reflection of the changes brought by this water treatment, two nearby sections were set up – AQUA4D® vs Control.

The Paulmans measure everything, so nothing is left to chance. For years, fields have been mapped for water holding capacity and scientific-grade weather stations provide real-time evapotranspiration stats. Alongside this, several further variables were monitored as part of the AQUA4D project, including AquaSpy probes to measure soil moisture, and crop monitoring imagery from Hemav.

By tracking the progress in real-time, Paulman and AQUA4D agronomists could suggest changes to irrigation practices. And, suffice to say, there were plenty of changes: “This year we ended up applying half the water on the AQUA4D side – 5 inches vs 2.5 inches – and the corn looks tremendously better on the treated side,” notes Zach. “Just with my eyes it’s very clear to see that something is happening – it’s not supposed to look like it does right now, I’ve never seen anything like it.”

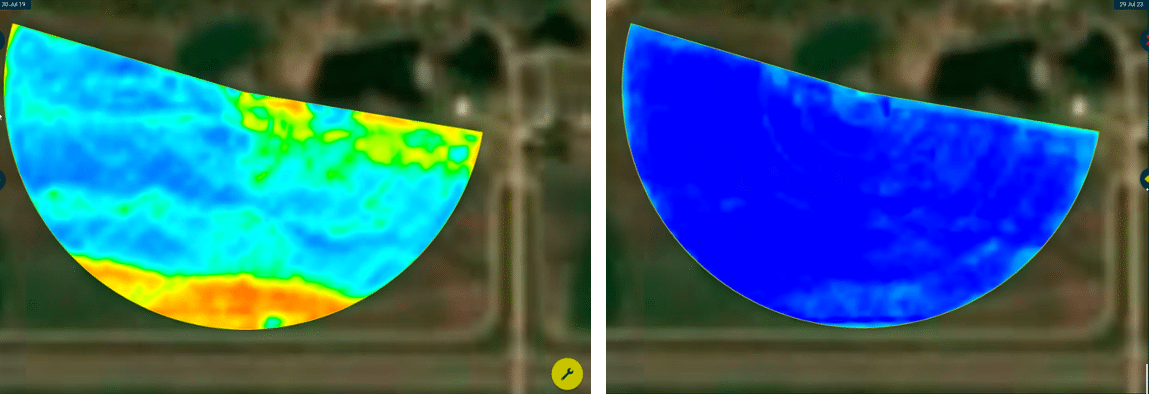

Anecdotal assertions are backed up by the NDVI imaging, which show extraordinary difference in the vigor of the AQUA4D field. The image on the left shows the situation prior to AQUA4D in 2019, while the image on the right is from August 2023.

Left: Before AQUA4D® (2019) | Right: After AQUA4D® (2023)

Field visits by the AQUA4D team confirmed the changes seen on the farm. As is often the case with this advanced water treatment, better water availability and nutrient uptake helped the roots develop better and the plants are healthier. This can also be seen as a result of better fertilizer dissolution; Zach believes that while they are already incredibly efficient with fertilizer application, the AQUA4D® treatment helps get the best out of the amount they do apply.

Here the plant on the left is from the AQUA4D side, and the one on the right from the control. It can be clearly seen that the root system is better developed, with more hairy rootlets:

Left: Impressive root growth | Right: Technical checks on the AQUA4D® system

Larger root systems are an indication of healthier plants and impressive eventual yields. Indeed, in 2022 there was a 40 bushel soybean difference on the AQUA4D side, which seems to have carried over to this year, as Zach believes in the lasting effect of what the system is doing. Understandably, the Paulmans are stoked to find see the yield data come harvest time later in 2023.

While these differences may be startling enough taken in isolation, Roric was quick to underline that these benefits have been achieved while applying 50% less water than the nearby control section: “We have enough data that shows some extraordinary health benefits and yield potential, all with less water use,” confirms Roric Paulman. “Achieving the same yield with less input – that’s what I call regenerative.”

Regenerative Irrigation

The effects go beyond improving the crops in the here and now. As reported elsewhere, AQUA4D® also leads to lasting changes within the porous soil structure. In the case of Paulman’s fields, the changes in their soil also meant better penetration by rainwater, meaning that the AQUA4D® effects extend even beyond irrigation. “Formerly, it was very hard to get water to go through the soil, it would usually just stay in the field and kill my corn. Now it’s much better, and I attribute most of that to the AQUA4D unit,” comments Zach.

With the farm located at the famously depleting Ogallala Aquifer, this leads to the decisive factor of recharge – as rain penetrates more deeply, it can recharge aquifers at the same time. This means not only are Paulman reducing pumping while irrigating with all they need, they are also recharging the same groundwater in Nebraska for future use – an elegant circularity.

This goes beyond Regenerative Agriculture into what can be termed Regenerative Irrigation. This could have huge implications for those who rely on pumping groundwater, in Nebraska and beyond, notes Zach Paulman: “We sit on the largest aquifer in the world, but it’s tough especially in the summer months when everyone is pumping like crazy. So it could be a really big deal for Nebraska if we can continue to look at what this AQUA4D unit is doing and why.”

Maximum Yield, Minimum Input

There is understandable excitement for the upcoming harvest – not to maximize the yield but to see if, as expected, they have managed to reach the same yield with much less resource. “The proof in the pudding will be in the final yield, and will give return on investment,” says Zach.“Right now it’s 7.2 inches vs 3.3 inches on the AQUA4D side. That’s crazy. By now I should be well over 10 inches on the whole pivot. It’s very interesting stuff.”

AQUA4D’s Jeff Nunes oversaw the project’s agronomic aspects. He agrees that minimizing inputs can ultimately help compensate for market fluctuations and in itself give a return on investment: “We have good years and bad years; what farmers need to do it reduce input costs so much that even if they sell at a lower price they will still be profitable,” he says.

Already persuaded by the benefits they’re experiencing, Paulman Farms are now setting up a second system on an adjacent field.

Conclusion

There’s no doubt that what Paulman Farms are doing has striking implications for growers in Nebraska and beyond. The combination of reg ag approaches and a technology for regenerative irrigation is showing others that it’s possible to thrive even in the face of dwindling resources.

By focusing on their inputs and on land stewardship – while not compromising on yield – Paulman are proving a middle way is possible, marrying business sense with sustainable decision-making. “It has to be this way,” confirms Zach. “Good Lord, if I can raise the same crop on half the water, that’s pretty incredible.”

His father Roric agrees: “Plant health, yield, sustainability, those are our yardsticks. We want to leave the ground in a better condition than we found it, and that is where AQUA4D has a place.”

Find out how the AQUA4D® H-A Max system works:

Nebraska, USA

Pivot Irrigation

Water Management

Soil Health

“Man alive, has it come a long way! Through farming practices, nutrient management, water management, and AQUA4D, I think we’ve come full circle and turned a piece of dirt into something incredible.” – Zach Paulman

“Plant health, yield, sustainability, those are our yardsticks. We want to leave the ground in a better condition than we found it, and that is where AQUA4D has a place.” – Roric Paulman